Quick and reliable adaptation of your satellite for the launch mission

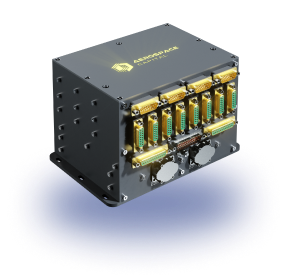

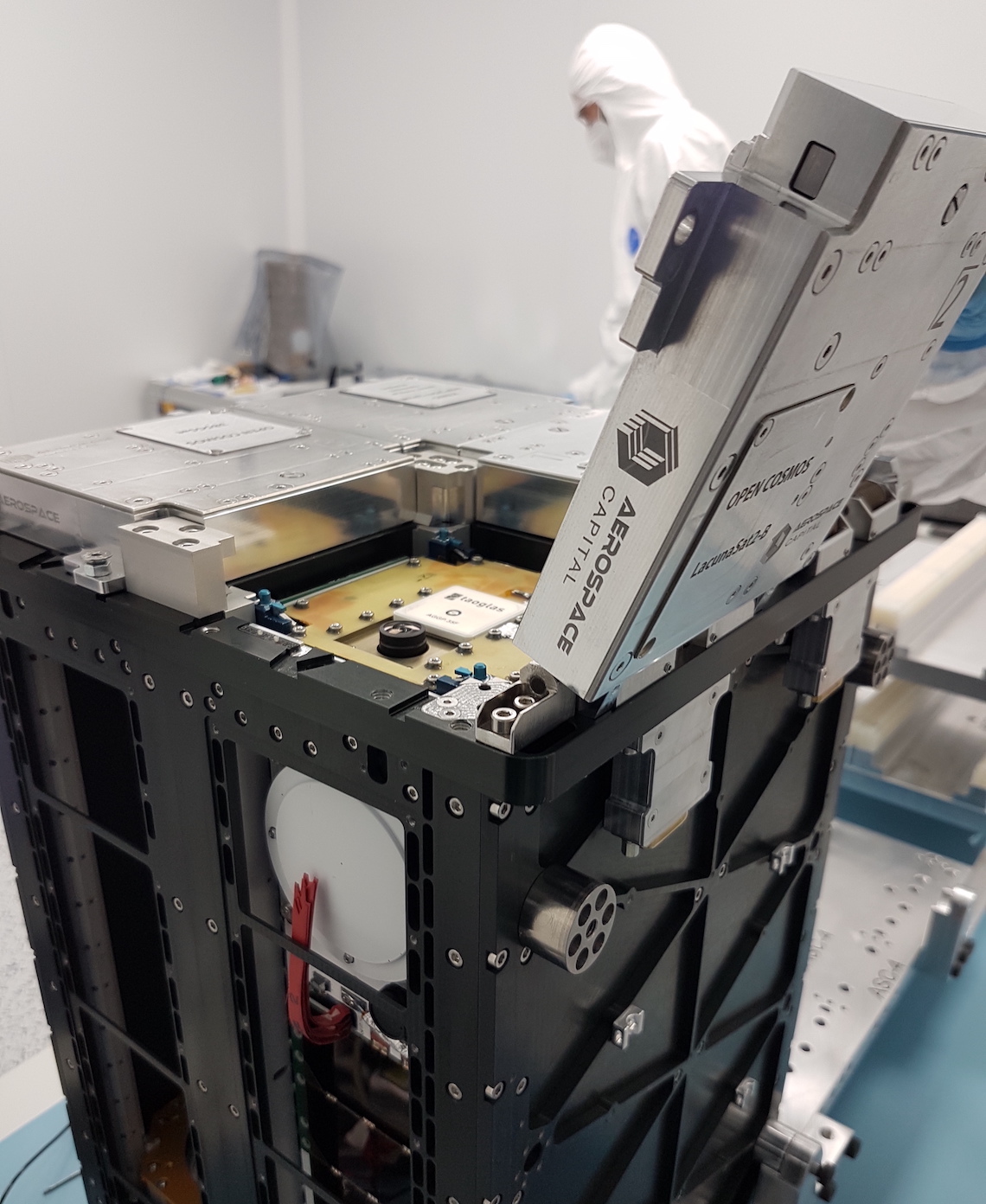

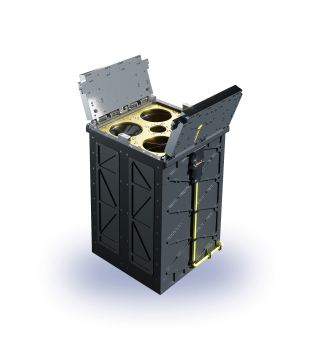

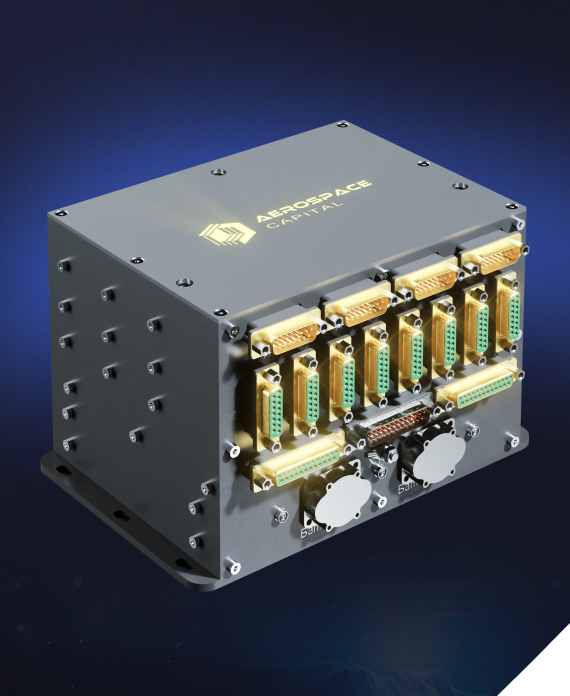

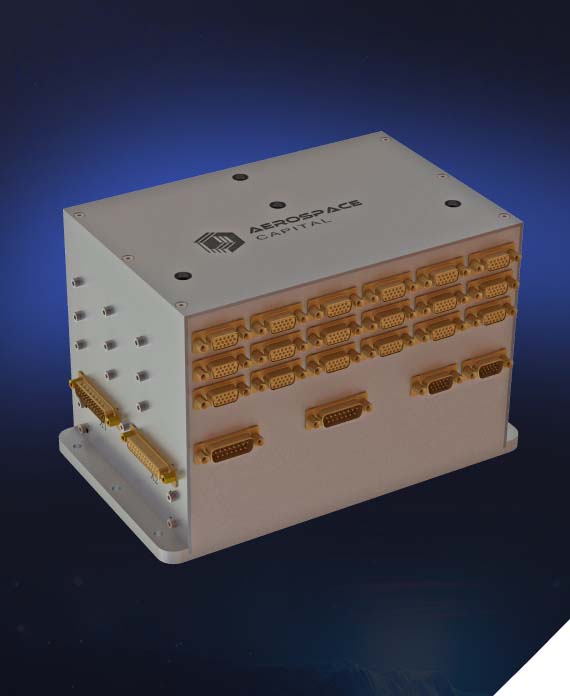

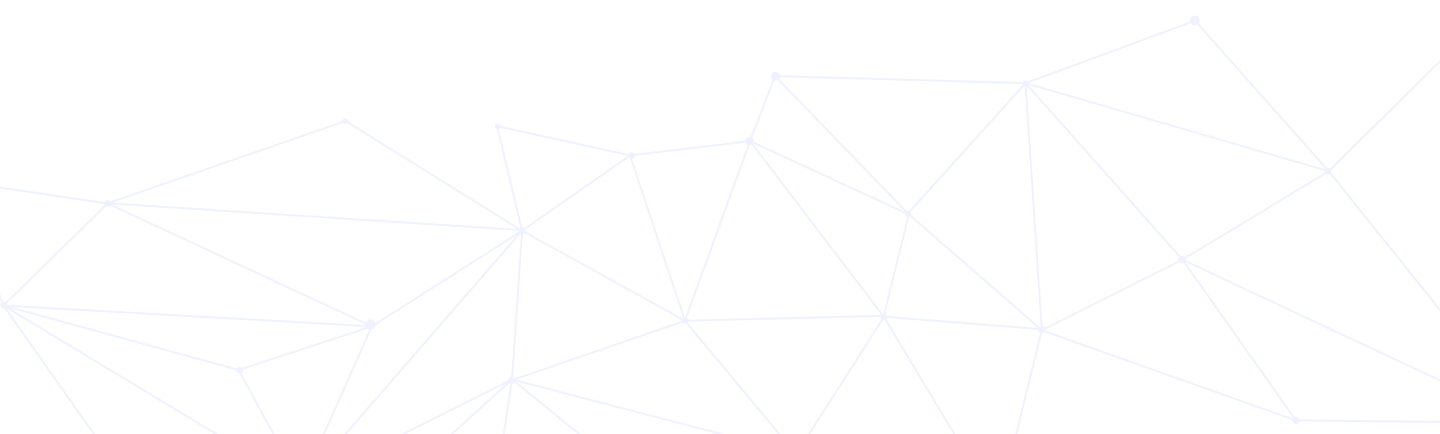

Aerospace Capital designs and manufactures CubeSat separation systems based on the in-house technical solutions that provide quick and reliable satellite adaptation to launch, satellite deployment in orbit with low tip-off rates, a cost-effective launch service, flexibility in adapting to non-standard requirements of satellites, and possible remote fit-check operations. Our current flight-proven products are 12U, 16U deployers, and a sequencer.

Our specialty is design and manufacture of separation systems for CubeSats and microsatellites

To date, 170 CubeSats successfully separated in orbit with the use of 59 Aerospace Capital deployers.

Our priority is the cubesat safety during launch and deployment

Our team (specialists in space robotics, mechatronics, electronics and drives, strength, spacecraft design), after a thorough analysis of the problems associated with CubeSat adaptation and orbiting, has developed a number of technical solutions aimed at reliable locking of satellite in a deployer slot during ascent by a launch vehicle, and the safe release of a satellite from the deployer. These solutions are implemented in the design of the deployers that our company offers for orbiting your missions. The pre-flight fine-tuning of the mechanisms and compliance with the set linear velocity of the satellite at separation have been worked out.

Ensuring reliability during SC launch and deployment

Design and manufacture

Stability margins in the design and operation of mechanisms

Redundant elements in the mechanical locking part

Quality control of the functioning of each movable element in the mechanisms

Redundant elements in deployer sequencer

Technical solutions that consistently ensure accuracy of the separation rails location after the deployer assembly

Independent development and testing of the door electromechanical devices.

Possibility to provide the specified value of the SC linear velocity at separation

Hide

Hide

Autonomous tests

Before launch, all elements of separation systems manufactured by our company undergo necessary scope of testing

Hide

Hide

Fine-tuning for SC deployment

The efficiency of mechanism unlocking is checked out at all stages of deployer assembling and testing

The optimal pre-load setting for the mechanisms when locking each CubeSat is done

During fit-check and SC integration: check-out of SC unlocking in a deployer slot

Hide

Hide

Safe SC orbiting

A set of technical solutions has been implemented and tested in space to ensure longitudinal and transverse locking of a spacecraft in the slot, to avoid any backlash between the spacecraft rails and the deployer slot rails during ascend

Anomaly protection systems, systems for spacecraft sequential unlocking and safe shockless separation of the spacecraft from the deployer have been introduced in the mechanical scope of the deployer

The deployer slots are equipped with switchers that indicate the status of mechanisms for the formation of telemetry about spacecraft separation

Hide

Hide

Company's services

We offer a full range of technical services: from the manufacture of separation systems to the adaptation and arrangement of launch services for CubeSats. We have gained experience in many aspects of CubeSat adaptation for launch using our in-house separation systems, and we are developing launch service capabilities based on our product line for the CubeSat market.

Our mission is to provide our customers with a successful result during the satellite adaptation, launch, and deployment in orbit.